ad3c.jpg?itok=6bfm-L_m)

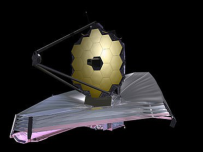

Six of the 18 gold-coated beryllium primary mirror segments in their test positions in the cryo vacuum chamber at NASA’s Marshall Space Flight Center X-Ray and Cryogenic Facility. Photo credit: NASA

NASA’s James Webb Space Telescope (JWST), named after former NASA Administrator James Webb (1961-1968), recently launched on December 25, 2021 to begin a groundbreaking campaign to expand our knowledge of the universe. Using infrared light, JWST will look back in time over 13 billion years and will enable a broad range of investigations across the fields of astronomy and cosmology, including observing some of the most distant events and objects in the universe, such as the formation of the first galaxies and detailed atmospheric characterization of potentially habitable exoplanets.

“Our unparalleled experience with advanced technology systems and our wide-ranging program support capabilities work together to support NASA in its quest to explore the universe,” says Jacobs Critical Mission Solutions Senior Vice President Steve Arnette.

Jacobs’ team members at several NASA centers have provided integrated solutions and superior technical support to help solve the most complex and hazardous challenges of development, test and launch of JWST.

Our contributions supporting NASA’s newest flagship mission include:

Advanced Operations and Testing for Space Exploration

At NASA’s Johnson Space Center (JSC) in Houston, Texas, Jacobs has supported the JWST program for over 14 years, modifying and upgrading the largest thermal vacuum chamber in the world — called Chamber A — and performing the official 100+ day cryo-vacuum test of the JWST Optical Telescope Element & Integrated Science Instrument Module in 2017. The team renovated the 50-year-old facility and integrated several new technologies never before utilized at this scale. By the end of the chamber renovation effort, Jacobs had installed three miles of new piping, a mile of vacuum jacketed tubing and more than 10 miles of wiring and optical cables. Despite challenging conditions brought on by the arrival of Hurricane Harvey in the midst of this critical test, Jacobs and JSC worked together to maintain stable test operations and complete this critical test on schedule, without interruption during the hurricane.

At the Marshall Space Flight Center (MSFC) in Huntsville, Alabama, Jacobs’ technical staff supported early testing of JWST components inside the X-Ray and Cryogenic Facility (XRCF). This one-of-a-kind facility simulates the extreme environments that space hardware is expected to withstand during space operations. The major components of JWST were tested at temperatures below -400 degrees Fahrenheit in the bus-sized vacuum chamber. The testing campaign lasted from 2008 to 2013 and included the 18 gold-coated beryllium segments of its 6.5-meter primary mirror, wings and primary mirror backplane support structure.

Technical Leadership for Successful Launch

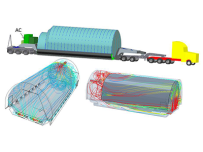

Jacobs’ staff performed Computational Fluid Dynamics (CFD) analysis during various stages of the JWST development program. One of the tasks was to analyze the potential for contaminants in the clean room at the launch site, modeling airflow with dust particles to determine particle tracks and impact points. Additional analysis was performed by TG staff to determine temperature contours and airflow ventilation needed to protect the telescope during transportation.

Jacobs’ team members on the Electrical Systems Engineering Services (ESES) III contract at NASA Goddard Space Flight Center provided logistical support to ensure that the breakdown, safe stowage and packing of support equipment used in observatory testing was completed safely, correctly and on-time.

Whether performing advanced operations and critical testing or providing technical integration, analysis and logistical support, Jacobs’ wide-ranging advanced technologies and solutions, spanning across multiple NASA Space Centers, contracts and programs, work together in support of NASA’s development, test and launch of JWST. For more on how Jacobs is redefining what’s possible, visit www.jacobs.com/insights/space-exploration.

2c4e.jpg?h=c7c14dee&itok=FmPI2126)

_0ac2b.jpg?h=8a6d63f3&itok=5vsqFiQH)

2747.png?h=1314d3d4&itok=rFs9mG95)